Formation theory of waterproof agent function

Index terms of waterproof agent

Solid content

It refers to the mass proportion of solid components of waterproof agent

Finished product

It refers to the product prepared and compounded on the basis of raw liquid.

Generally, the solid content is between 10%-18%.

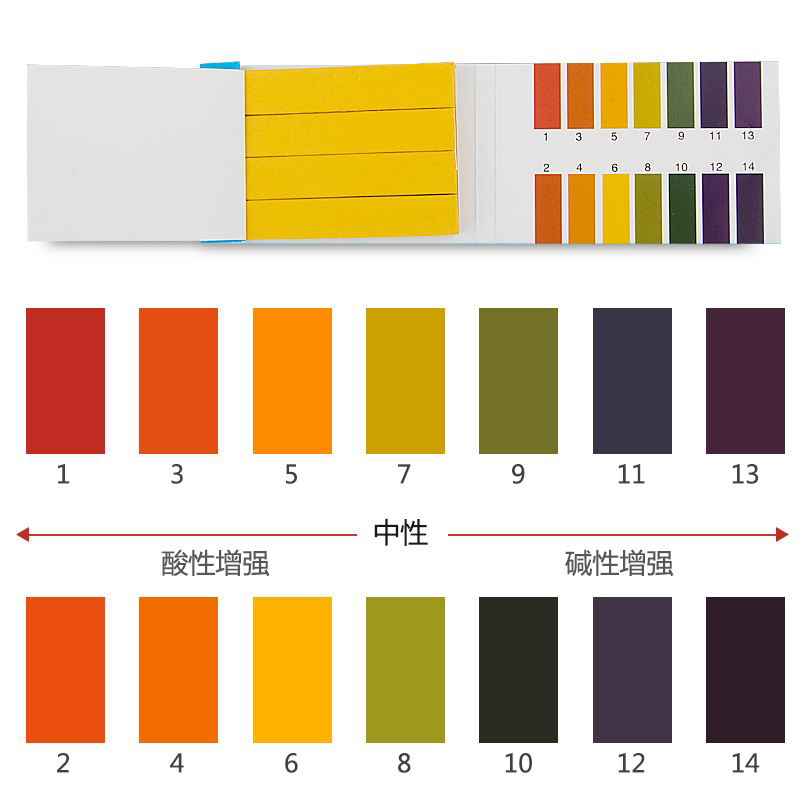

PH value

It refers to the PH, which has 1 to 14 values from acid to alkali. The PH value of waterproof agent is mostly between 3-5.

Original liquid

Generally, it refers to the waterproof agent that has not been prepared after being synthesized in the direct reactor, which is also called the raw liquid of waterproof agent. Usually the solid content is 30%,or 32 / 34 / 36%,no more than 36%.

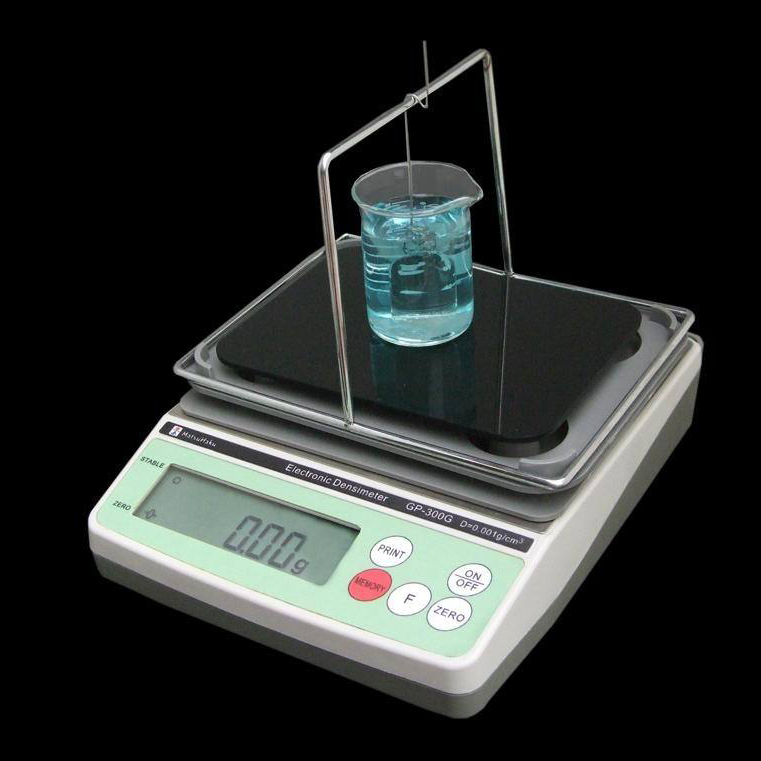

Proportion

It refers to the mass difference of the same volume compared with water. For example, the proportion of fluorine grease is relatively large. There is only half a barrel of 200 kg of fluorine grease, but only 100 kg of acrylate can be loaded.

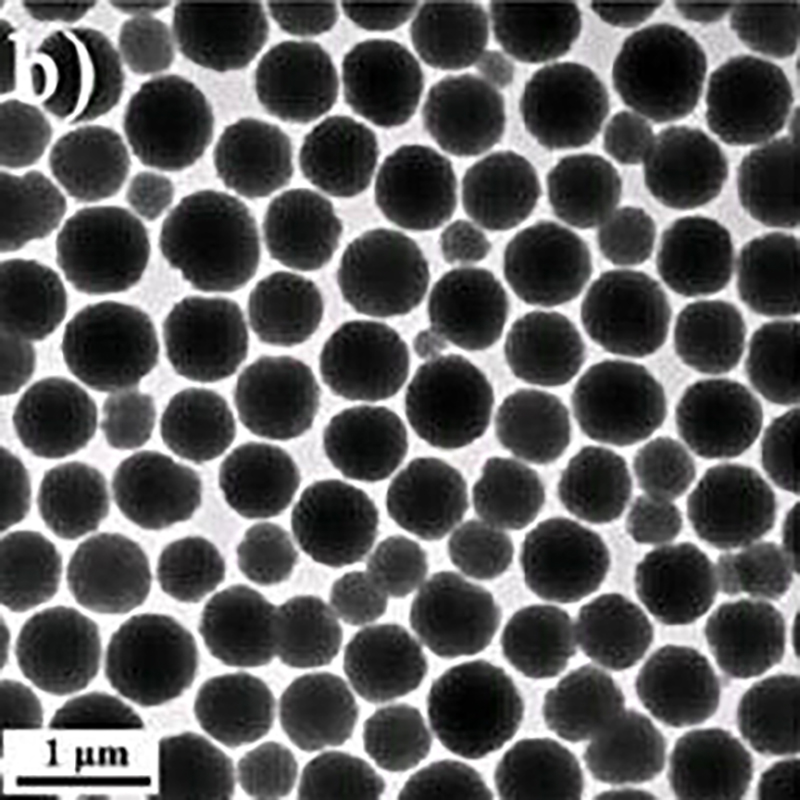

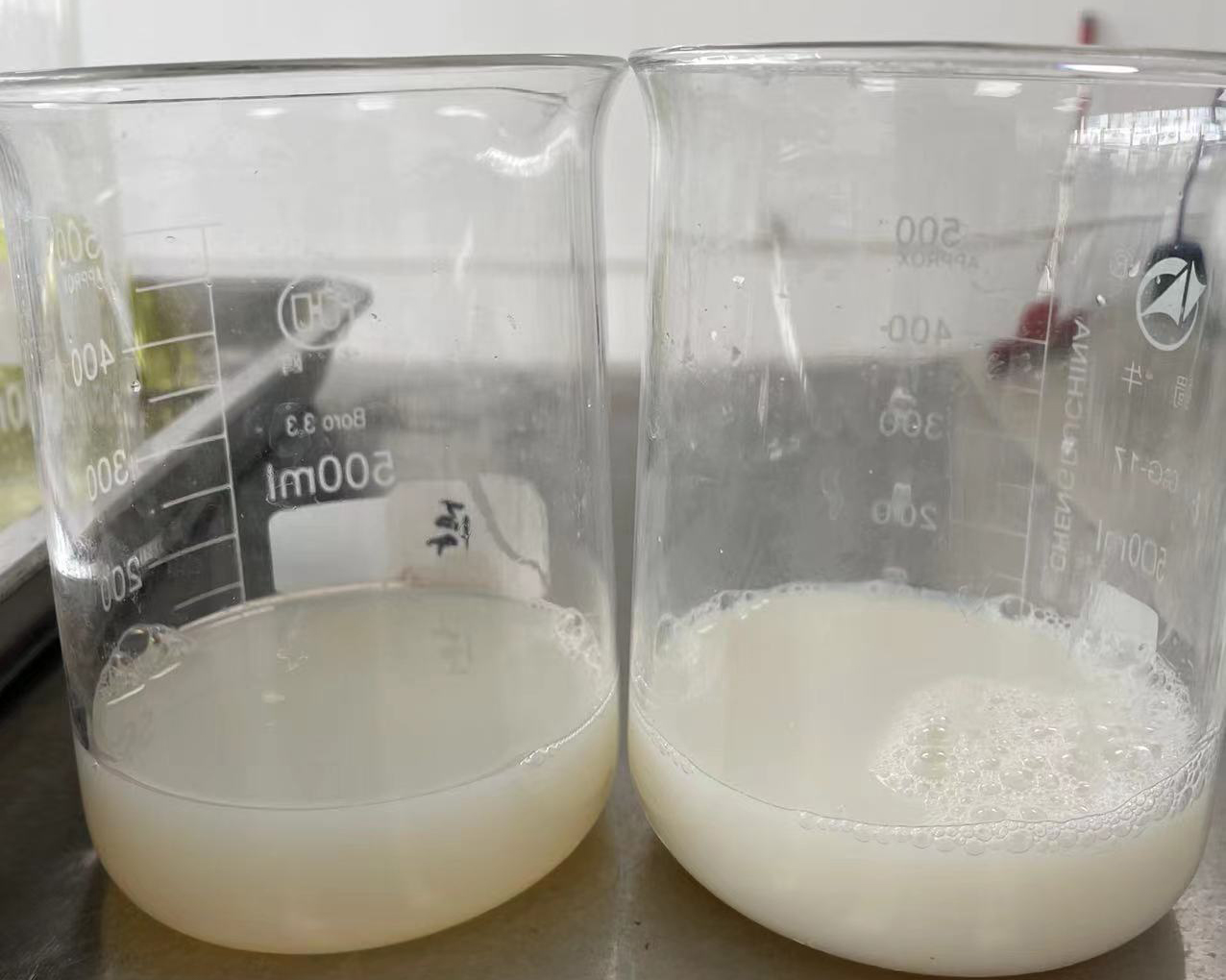

Particle size

It refers to the molecular diameter of lotion, generally 80-200 nm. The smaller the particle size, the better the transmittance, and the larger the particle size, the more milky white the color.

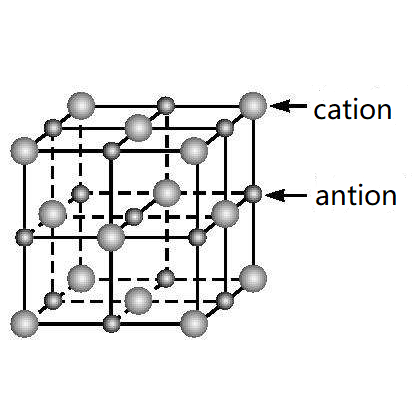

Lonic type

It refers to that in aqueous solution, the electrolyzed H+ ion is called cationic waterproof agent, the electrolyzed OH- is called anionic waterproof agent, and there are non-ionic waterproof agents.

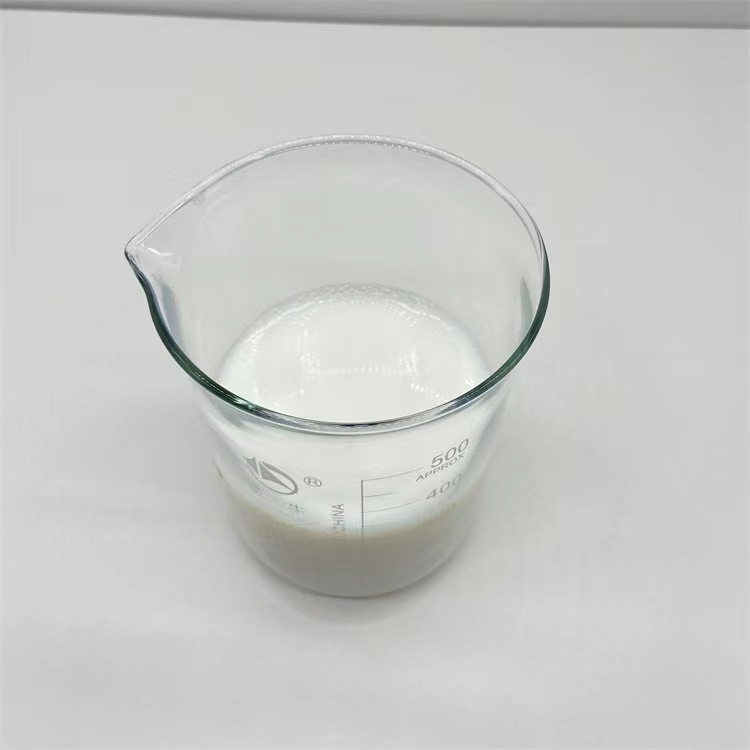

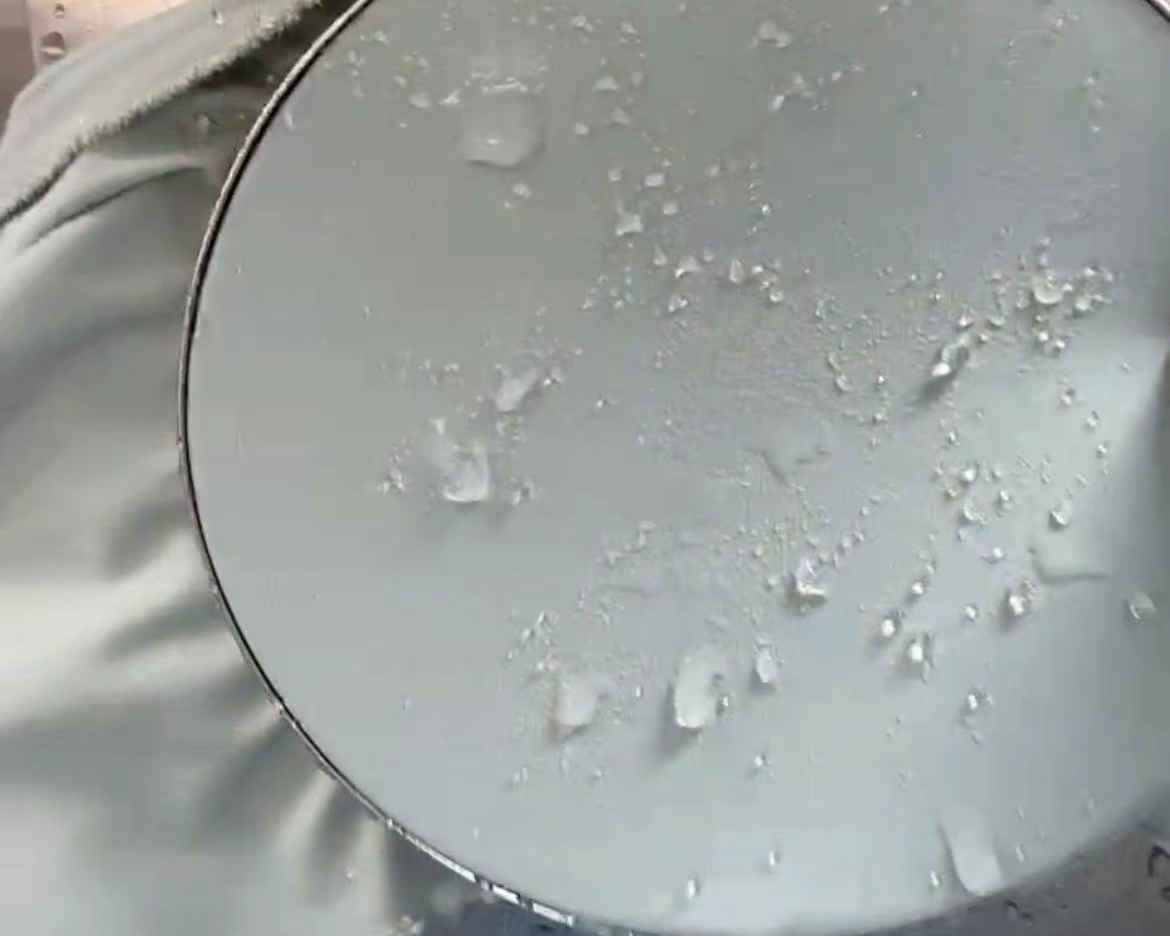

Solubility / appearance

Waterproof agent is infinitely soluble in water.

The appearance is usually milky white or translucent yellowish.

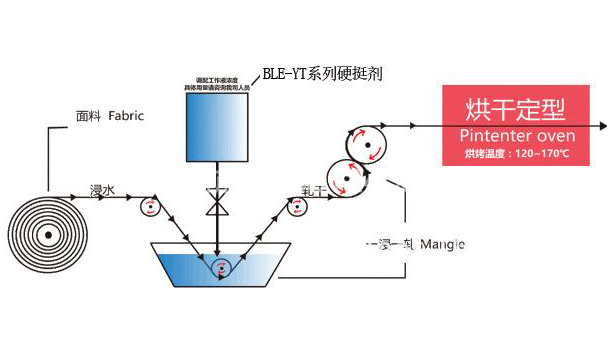

Processing method of waterproof agent on fabric

Mode1

Dipping: one dip one rolling,one dip two rolling,two dip two rolling.

Mode2

Spraying method: spray evenly with spray after dilution

Mode3

Garment:Soaking, spin-dry and drying of large washing machine

How to judge the performance of waterproof agent

Waterproof stability

Good waterproof stability, not easy to stick, not easy to blister, no waterproof strip

Waterproof universality

It refers to the wide adaptability of fiber types, such as polyester, nylon, cotton, blending, etc

Waterproof level

Simple test, water sprinkling method, water dipping method, water pocket method

Waterproof and lifting performance

It refers to the curve of increasing the waterproof fraction of concentration

Oil resistance

The oil proof grade also reflects the waterproof performance

Washing durability

There are water washing, dry cleaning, drying and air drying, which is also called shade drying

Problems arising from the application of waterproof agent

01

Poor waterproof performance

The waterproof effect is not good. It depends on the comparison,cost performance,dosage, fabric, processing method, dry cloth or wet cloth. These are the factors affecting the waterproof effect

02

Poor waterproof continuity

Depending on the pH value of the working fluid, the alkaline waterproof effect will decline, the effect persistence of wet cloth will be poor, and the persistence of dye residue in the fabric will also be poor

03

Poor compatibility

The choice of waterproof stock solution is very important. What structure of waterproof agent should be selected for compounding and matching

04

Not resistant to washing

Is there any cross-linking agent added? Is the waterproof agent originally a water-resistant waterproof agent

05

Color change

All organic fluorine will make the color dark. You should be prepared in advance

06

Waterproof strip Waterproof stain

The main reason is that the feeding method may cause waterproof strips and waterproof stains

07

Too much foam

The main reason is that the fabric is too dirty

08

Poor hand feel

It depends on what kind of hand feel the customer needs, hard or soft

Problems arising from the application of waterproof agent

01

- What water is used, recycled water, tap water, groundwater or mountain spring water ?

02

- Whether there are dye residues, anion residues and other slurry residues ?

03

- Whether the pressure roller is aging, whether the pressure is uniform and whether the temperature reaches ?

04

- Whether it is standard, whether it needs high-level chute feeding, whether the mixing is uniform, whether the chute is clean, and whether the feeding tools are clean?

05

- Whether the temperature is enough, whether the time is enough, and whether the speed is ideal ?

06

- What type of waterproof agent and what price of waterproof agent ?

07

- Whether the mixing speed is too fast and whether it is affected by shear force?

08

- Is the calendering temperature too high and the pressure too high?