Full-Scenario Adaptation! Eco-Friendly Technical Solution for Full-Dimensional Anti-Siphonage in Shoe Material Webbing / Upper / Insole

The Siphon Phenomenon and Anti-Siphonage Requirements for Fabrics

The siphon phenomenon is a physical effect that utilizes the force of liquid level difference to draw water from a lower position to a higher one. The siphon phenomenon in fabrics is similar to the capillary effect: when fabrics come into contact with water, the water will spread and diffuse to the higher parts of the fabric through the fabric structure.

With the improvement of consumers' living standards, there is an increasingly common demand for fabrics to undergo waterproof and anti-siphonage finishing. For instance, products such as webbings, ropes, shoe uppers, and yarns all require anti-siphonage performance.

I. Principle of Anti-Siphonage

It is mainly achieved by altering the surface energy of the material. After treatment, a lotus leaf-like hydrophobic layer is formed on the fabric surface, making it difficult for moisture to diffuse through the fiber gaps to higher positions.

II. Anti-Siphonage Finishing of Fabrics

The anti-siphonage performance of fabrics is usually achieved through finishing with water repellents, so the selection of a suitable water repellent is crucial.

Suzhou Leman uses the high-end fluorine-free water repellent WSP-02D to treat shoe materials, resulting in an excellent anti-siphonage effect. After waterproof treatment, the fabric is left to stand for 12 hours, and no significant rise in the anti-siphonage effect is observed within 2 hours. Generally, customers require that the rise of the anti-siphonage effect be less than 10mm to be qualified. WSP-02D can be used for anti-siphonage finishing of various fabrics, and its effect is superior to other anti-siphonage water repellent products available on the market.

Anti-Siphonage: Classification into Static and Dynamic Types

Anti-siphonage can be divided into two main categories: static anti-siphonage and dynamic anti-siphonage. Static anti-siphonage adopts the static suspension method, where the qualification is evaluated by observing whether the liquid immersed in the fabric rises and measuring the height of the rise. Below is an application example using the static anti-siphonage test for shoe materials.

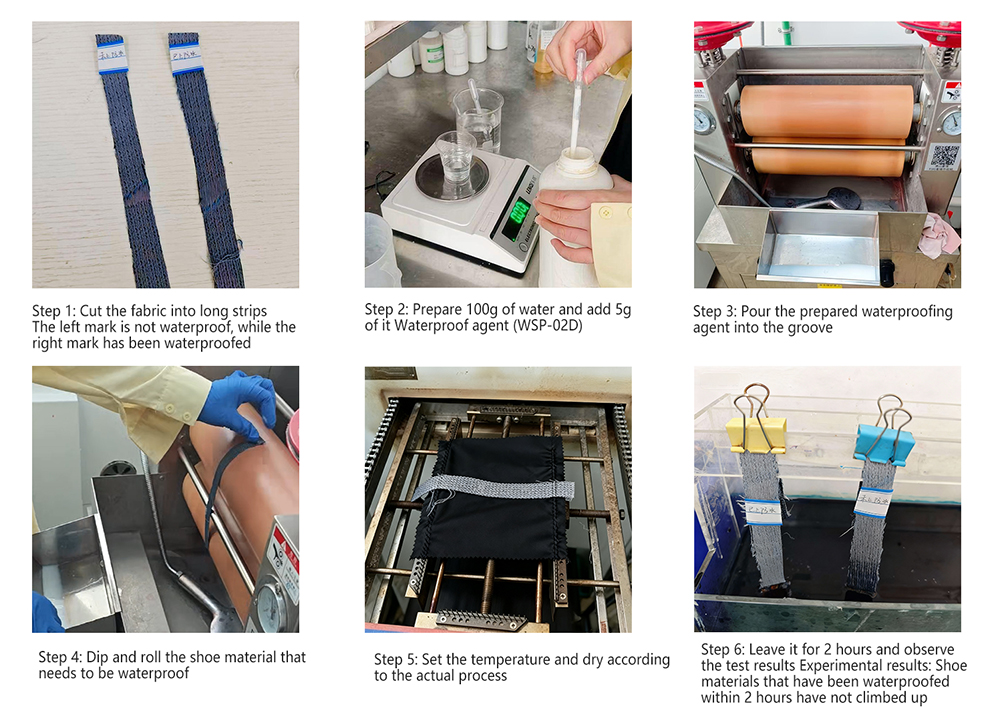

III. Practical Case

Fabric: Shoe Material Fabric

Formula: Fluorine-free Water Repellent Agent WSP-02D (5%)

Process: One Dip and One Pad; Curing at 150°C for 4 minutes

Test results

| Product Name | 2H climb altitude/mm | notes |

| Fluorine free waterproofing agent WSP-02D | 0 | After waterproof treatment, the shoe material is tested for siphoning after being left for 12 hours |

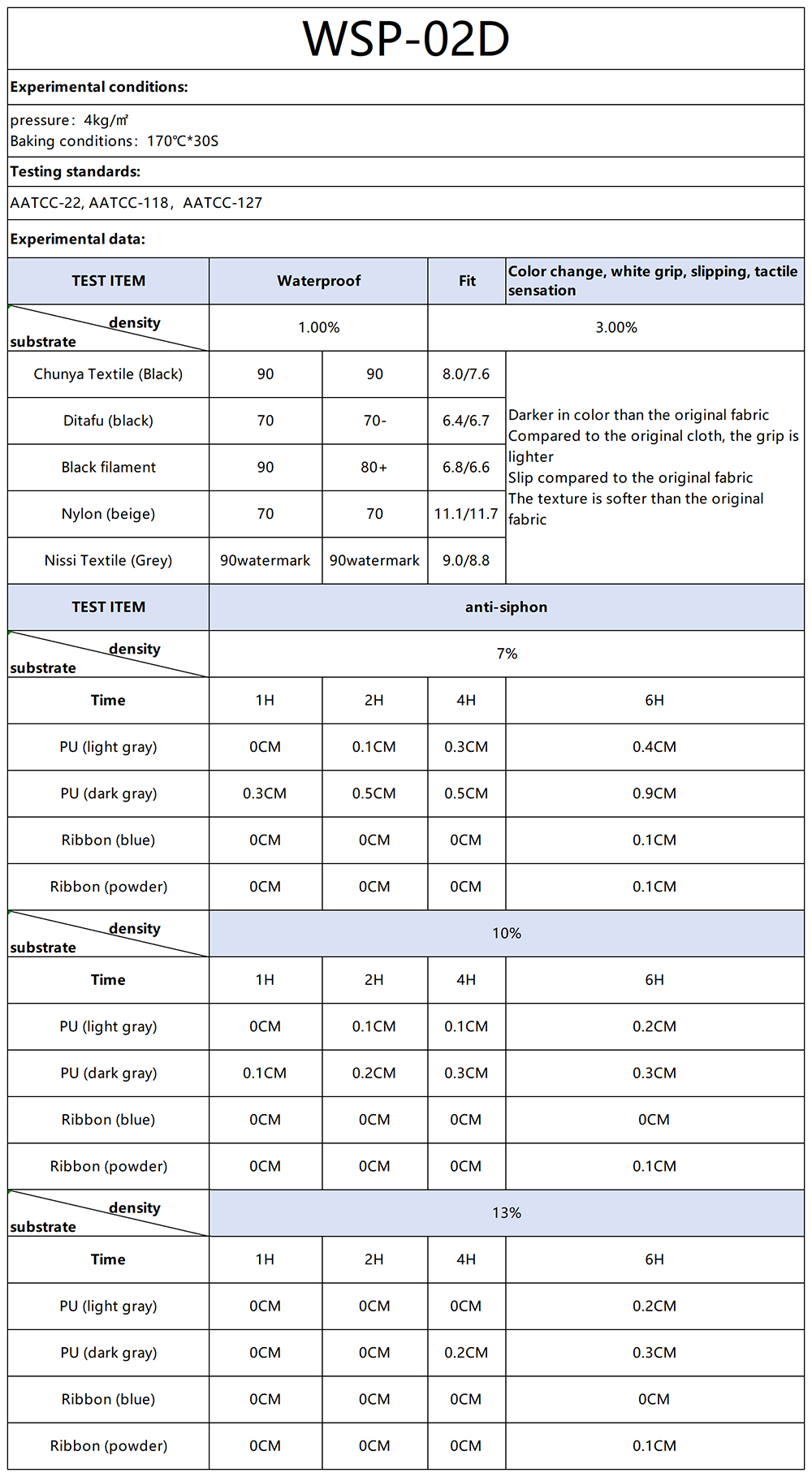

WSP-02D Specific Experimental Data Report:

We conducted a series of anti siphon tests on more materials (PU, webbing, etc.) using the above experimental steps. By changing the dosage of WSP-02D, as shown in the table below, with a waterproofing agent dosage of ≤ 10%, the anti siphon effect can meet the requirements (climbing height<10mm).

Product functional features

Excellent waterproof performance: After water repellent treatment, the surface tension of the fabric changes, and the fabric changes from hydrophilic to hydrophobic. Water droplets on it are like droplets on a lotus leaf, rolling but not wetting.

Excellent anti siphon effect: The fabric based on the modified polyurethane lotion has "excellent anti siphon effect", which is essentially to completely block the "hidden water seepage" by "physically blocking capillary channels+chemically weakening the siphon attraction+durability of the structural guarantee membrane" - it is not only a supplement to the "surface water repellent", but also a key technical support for upgrading the fabric from "surface water repellent" to "full penetration resistant", which directly determines the practical value of the fabric in wet scenes.

Fluorine free and environmentally friendly: using water as the dispersing medium, the VOC content is usually less than 30g/L (much lower than 300-500g/L of solvent based waterproofing agents), and does not contain prohibited substances such as formaldehyde, heavy metals, APEO (alkylphenol polyoxyethylene ether), which complies with the EU OEKO-TEX standard ® Standard 100 (infant grade textile standard) and domestic GB 18401 (textile safety technical specifications) can be used for waterproof treatment of close fitting clothing and infant fabrics.

Synergistic waterproof and breathable: different from the traditional "impermeable waterproof membrane" (such as PVC coating), the membrane formed by the modified polyurethane lotion is a "porous network structure" - micropore size (0.1-1 μ m) can block water droplets (about 10-100 μ m in diameter), but allows water vapor molecules (about 0.0004 μ m in diameter) to pass freely. According to GB/T 11048 (fabric moisture permeability test), the moisture permeability can reach 5000-10000g/(m ² · 24h), meeting the respiratory needs of human skin and avoiding "sweating" when wearing. It is the core advantage of outdoor clothing and sports fabrics.

Friction and environmental resistance: Polyurethane itself has high elasticity (elongation at break of 200% -500%), which can stretch with the deformation of fabric fibers, avoiding membrane damage caused by friction.

Simple process and strong compatibility: the viscosity of lotion is adjustable (50-500mPa ・ s), which can be applied through conventional textile finishing processes such as dip rolling, spraying, coating, etc., without special equipment; And it has good compatibility with the pre-treatment (such as desizing and bleaching) and post-treatment (such as softener and wrinkle inhibitor) processes of fabrics, without process conflicts, making it suitable for large-scale industrial production.