Washing waterproof fabrics have waterproof performance, which involves the tolerance of waterproof fabrics. Most waterproof fabrics use high -temperature drying to dry the fabric when studying their washing resistance.

For example, after the waterproofing of the four -sided bomb fabric, it usually takes about 100 ° C to dry at about 100 ° C to restore a good waterproof effect. Although some domestic washing machines have their own drum drying function, this is not common, and the drying method of high temperature drying is not commonly used. The drying method commonly used in my country is to hang drying. Therefore, studying naturally drying can restore the waterproof effect of good waterproof effect.

1. Research on the impact of waterproof performance after washing

First of all, we need to clearly know that there are many factors that affect the waterproof performance of the fabric, such as the choice of waterproofing agent, the choice of cross -linking agent, the adjustment of the waterproofing process, and so on. This experiment mainly studies the choice of waterproofing agents and cross -linking agents. The fixed waterproof collation process is as follows:

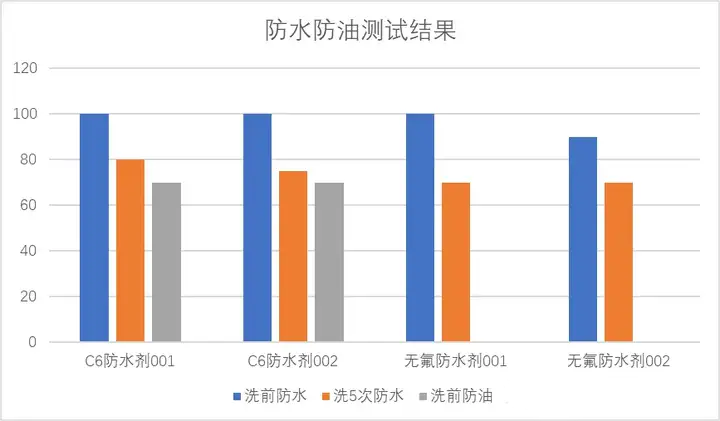

Waterproofing agent XG/L, cross -linked agent YG/L, rolled one by one (3kg/cm2), dried, high -temperature roasting (130 ~ 150 ° C, 30-120 seconds), after room temperature to return, test fabrics, test fabric, test fabric, test the fabric, and test the fabric, and test the fabric, and test the fabric. The initial and washed 5 naturally dry fabric waterproof and oil -proof effect. The test results are as shown below:

Conclusion: From the figure above, it can be seen that after the waterproofing, the initial and washing of the fabric and the waterproof effect after drying 5 times, the C6 waterproof agent is higher than the fluorine -free waterproofing agent.

Reason analysis: This is because the fluorine -containing monomer in C6 waterproof agent is an active ingredient for waterproofing effect. The higher the content of fluorine -containing monomers, the better its waterproof oil and anti -prevention effect. Because the fluorine -free waterproof agent does not contain fluoride, it cannot form a comb structure to reduce the surface tension of the fabric. Therefore, the lower its waterproof effect is lower than the fluorine -containing agent and no oil -proof effect.

2. Examination of cross -linked agents

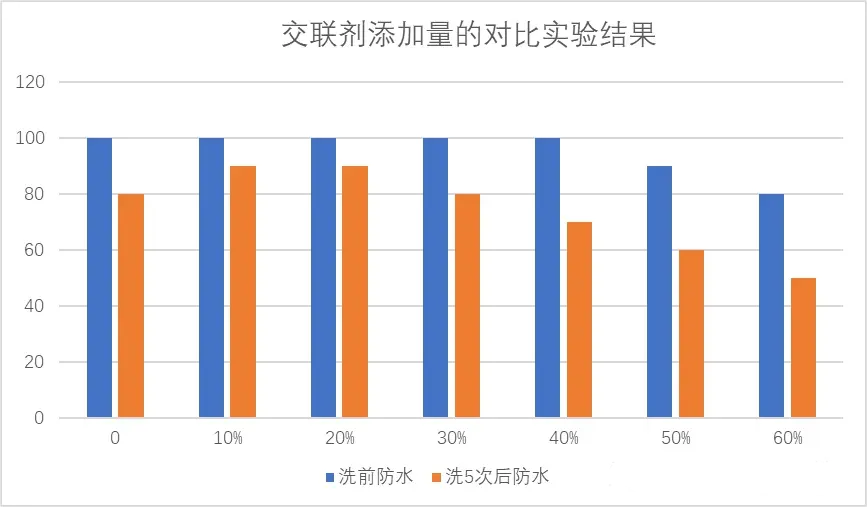

The amount of the cross -linked agent in this experiment is a range, that is, 0 to 60%of the amount of waterproof agent dosage. The test results are shown in the figure below.

Conclusion: From the figure above, it can be concluded that the waterproof performance of the fabric after washing has a greater impact on the waterproof performance of the fabric (both decreased significantly). After joining the cross -linked agent, the fabric can improve the washing resistance. It can be concluded from the figure above that the amount of the linked agent is the best to wash the fabric when the waterproof agent is 10%to 20%. And after increasing the amount of cross -linked agent is greater than 20%, the waterproof performance of the fabric is reduced and will affect the waterproof performance before washing.

Reason: This is because the more the linked agent is not as good as possible. Excessive crosslinkers will cover the surface of the fabric, so as to prevent the waterproof agent from crossing the surface of the fabric into a film, then the waterproof performance of the fabric will naturally decrease.

3. Conclusion and suggestions

Although the waterproofing agent, cross -linked agent and its appropriate amount and process of experimental fabrics were found through experiments, each fabric was not universal, and each fabric was selective for waterproofing agents and cross -linked agents. The same process ratio is actually not suitable for all fabrics, so if you think of the waterproof and oil -proof effect you need, it is recommended to test the fabric, fabric, clothing, or cloth board to the professionals to find the best auxiliary agent to find the best auxiliary agent By ratio and corresponding process conditions.

LeMan Suzhou Polymer Technology Co., Ltd, mainly engaged in fluoride waterproof, carbon eight waterproofing agents, carbon six waterproof agents, solvent waterproofing agents, mainly used in the fields of textile fabrics, leather, filter materials, paper mold plastics and other fields. With senior R & D team and rich application experience, you can customize personalized functional collation solutions according to the characteristics of fabrics and development needs. Various types of textile functional development consultation and technical exchange welcome email: info@lemanpolymer.cn

Post time: Apr-28-2024