first, waterproof performance

| standard number | standard name |

|---|---|

| GB/T4745-2012 | "testing and evaluation of waterproof performance of textiles water staining method" |

| AATCC 22-2014 | water repellency: a spray test |

| ISO 4920:2012 | "textile fabric surface moisture resistance determination of water stain test" |

| AATCC 193 | "wetting resistance: waterproof/alcohol solution test" |

thereinto:

GB/T 4745, AATCC 22 AND ISO 4920 WERE ALL TESTED USING A LEFT-HAND SPRAY DEVICE.

evaluation criteria:

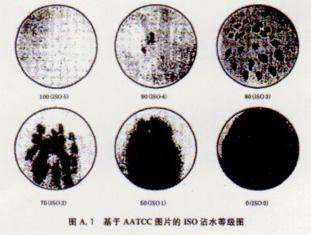

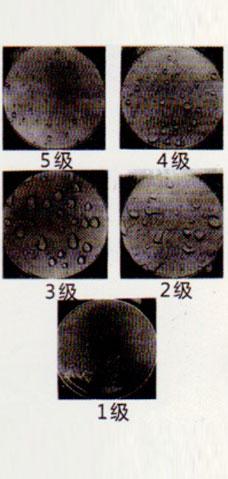

GB is consistent with ISO standards for 0-5 grades, with 5 levels being the best;

AATCC is a 0-100 scoring standard with 100 points being the best.

The evaluation criteria and correspondence are shown in the figure on the right.

The AATCC 193 standard differs from the above standards in that it uses a gradient surface tension test solution (water and isopropanol mixture).

Operation Brief Description

The prepared grading test droplets are held on the finished sample cloth for 10 seconds, and the infiltration is observed from multiple angles, and the rating rating is the highest level of the test solution that is not infiltrated.

evaluation criteria:

| water repellency level | water: isopropanol |

|---|---|

| 0 | 100:0 |

| 1 | 98:2 |

| 2 | 95:5 |

| 3 | 90:10 |

| 4 | 80:20 |

| 5 | 70:30 |

| 6 | 60:40 |

| 7 | 50:50 |

| 8 | 40:60 |

2 rain test

| standard number | standard name |

|---|---|

| GB/T 14577-1993 | determination of water repellency of fabrics bondis gate rain shower method |

| ISO 9865:1991 | "determination of water repellency of fabrics by bondi gate rain test for textiles" |

| HE L 1092:2009 | "waterproofness test method for textiles" |

| AATCC 35-2013 | water repellency: rain test |

thereinto:

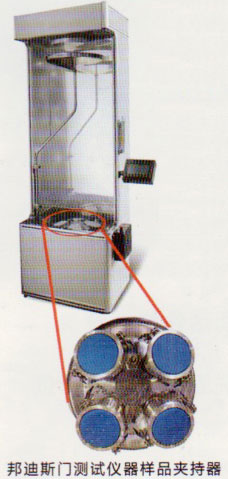

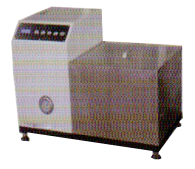

GB/T 14577, ISO 9865 AND JIS L 1092 WERE ALL TESTED USING THE LEFT FIGURE BONDIS GATE RAIN TESTER.

operation description:

in the bondis door tester, the arranged sample cloth is clamped on the gripper, there is a scraper blade under the gripper, the gripper rotates automatically during the test, and the scraper moves back and forth under the fabric to simulate the dynamic rain process, and the test standard time is 1, 5, 10, 15 minutes.

evaluation criteria:

The rating criteria are consistently 1-5, with 5 being the best.

Note:

1, the surface water exposure evaluation is different from GB/T4745;

2, the test time has a great impact on the rating, you need to indicate the test time.

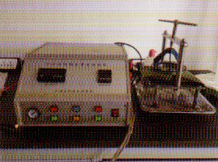

The AATCC35 is tested using a rain tester, as shown in the figure below.

Operation Description

A standard absorbent paper is placed on the back of the test fabric and the specimen is clipped to the specimen holder. Place the specimen in the middle of the spray, at a certain distance and water pressure, and spray continuously for 2 minutes. After the spray, the absorbent paper is weighed and the weight gain value of the absorbent paper is recorded.

Evaluation criteria:

not graded, according to the absorbent paper absorbent weight gain for evaluation, generally required to increase weight less than 1g, other special circumstances according to the blister paper weight gain quality evaluation.

second, oil-proof performance

oil-proof test

| standard number | standard name |

|---|---|

| GB/T 19977-2014 | "textile oil repellency anti-hydrocarbon test" |

| AATCC 118-2013 | "oil repellent anti-hydrocarbon test" |

Operation Description:

Drop the grading test oil on the finished sample cloth, hold it for 30 seconds, and observe the wetting situation from multiple angles, and the rating is the highest level of test oil that is not infiltrated.

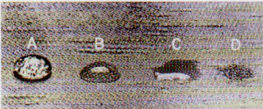

The above figure shows the diffuse criterion figure

A: passed, completely unenved

B: edges passed, a small part was infiltrated

C: did not pass, most of it was infiltrated

D: did not pass, completely infiltrated

evaluation criteria:

there are 1-8 grades of grading evaluation criteria, and 8 levels are the best.

| oil repellent rating | use reagents |

|---|---|

| 1 | white mineral oil |

| 2 | white ore oil: n-hexadecane (65:35) |

| 3 | hexadecane |

| 4 | n-tetradecane |

| 5 | n-dodecane |

| 6 | henonine |

| 7 | n-octane |

| 8 | heptane |

Third, hydrostatic pressure

GB/T 4744-2013 "Textile waterproof performance testing and evaluation of hydrostatic pressure method"

Operation description:

The method uses the hydrostatic pressure of the fabric to express the resistance encountered by water through the fabric. Under standard atmospheric pressure conditions, one side of the specimen is subjected to a continuous increase in water pressure until there are three seeps of water, and the pressure at this time is recorded.

Unit Conversion:

Common units in actual use are mm· H2O、m·H2O、KPa

10 KPas≈1m· H20=1000mm· H2OR

Hydrostatic pressure test equipment for coated fabrics (test hydrostatic pressure can reach 6m· H2O)

Hydrostatic pressure equipment for uncoated fabrics (hydrostatic pressure is less than 1000mm. H2O)

fourth, anti-fouling performance

easy to decontaminate (washing method).

| standard number | standard name |

|---|---|

| AATCC 130-2010 | decontamination: oil stain removal act |

| FZ/T 01118-2012 | "textiles testing and evaluation of textile properties easy to decontaminate" |

Operation Description:

Apply a certain amount of stains to the textile, retain it for a certain period of time, and evaluate the extent to which the stain is removed after washing under the specified conditions.

Evaluation criteria:

There are 1-5 grades of grading evaluation criteria, and 5 levels are the best.

Regarding test stains:

Stains in FZ/T are classified as industrial pollutants (dirty motor oil) and non-industrial pollutants (peanut oil), and stains in AATCC are only corn oil.

Fifth, anti-acid and alkali

anti-acid and alkali test

| standard number | standard name |

|---|---|

| GB 24540-2009 | 《protective clothing acid and alkali chemical protective clothing》 |

| BS EN 13034-2005 | "performance requirements for chemical protective clothing with limited protective effect on liquid chemicals (type 6 equipment)" |

GB 24540-2009 Appendix A anti-acid permeability time test evaluation criteria:

There are 1-3 grades of grading evaluation standards, and 3 levels are the best. The infiltration time before washing ≥ 30min, the ≥ 10min after washing is the level 3 standard, and the washing condition is continuous washing for 4 hours.

GB 24540-2009 Appendix D in the liquid repellent efficiency test evaluation criteria

are not graded, requiring a liquid repellent index ≥ 90%.

BS EN13034-2005 in the liquid repellent efficiency test evaluation criteria:

There are 1-3 grades in the grading evaluation criteria, 3 levels are the best, the permeability index < 10% is 1 grade, the < 5% is 2 grades, and the < 1% is 3 grades.

About the test liquid:

The test solution in GB is 80% sulfuric acid, 40% nitric acid, 30% hydrochloric acid, 30% sodium hydroxide, 30% sulfuric acid, 10% sodium hydroxide, o-xylene, n-butanol in BS EN.