Leather products have been widely demanded since ancient times. The application of leather can be traced back to the Paleolithic era. At that time, our ancestors were able to apply animal leather to sewn leather clothes. With the continuous reform of the technology technology, people’s requirements for leather products have also continued to improve. From simple “raw skin” to “cooked skin” to pursuing the production of multifunctional leather with excellent performance such as waterproof, oil -proof, flame retardability. At the same time, the emergence of artificial leather with special excellent performance challenged natural leather.

Waterproof is an indispensable feature of modern leather. The most widely used clothing leather and upper leather demand for waterproofing is increasing day by day. For many leather products, people’s purchase conditions have also added the “waterproof”. The widespread application of waterproof revolution makes waterproof seems to be one of the characteristics of the leather itself. Today, many waterproof process technology has been developed. This series has systematically summarized the relevant content of leather waterproof research from three aspects: leather waterproof concept, waterproof mechanism, and waterproof process technology. This article mainly explains the concept and mechanism of waterproof.

1. The basic concept of leather waterproof

The key to leather waterproof is to prevent water from invading the other side of the leather through the leather side. Because the leather itself is hydrophilic, the natural leather is generally tanned and it cannot prevent this process. The hydrophilicity of the leather is composed of collagen fibers woven in three -dimensional space, and there are countless capillary tubes with different radius between fibers. After tanning, the addition of chemical materials has introduced more polar groups, such as hydroxy, carboxyl, and amino groups. Due to the principle of similar compatibility, these polar groups can form a bond with water. Combine.

After the leather was in contact with water, the existence of a large number of polar groups caused leather to be hydrophilic and moisture wet leather. At the same time, the existence of thin tubes in the leather enabled the leather to absorb water into the leather. And waterproof is to block the occurrence of the above process, so waterproof can be summarized into the following three:

(1) No moisturizing: Prevent the characteristics of the surface of the epithelial fibrin, which is wet on the surface of water, is water reference.

(2) No water absorption: the performance of preventing leather from absorbing water and infiltrating inward, that is, water resolution.

(3) Precision water: The performance of preventing water from entering the leather side to the other side, namely Water Proof.

The above are three aspects of waterproof performance. The waterproof performance should include these three aspects, which refers to the ability of leather to resist water absorption, water permeability and wetting by water. However, the waterproof performance of the existing waterproof leather often does not have both three. For example, although some waterproof leather can be wet on the surface, it can prevent water from penetrating into the leather. Refusal; although some waterproof leather cannot be wet on the surface, its dynamic waterproofness is poor. The existence of this phenomenon makes people’s understanding of waterproof leather more chaotic. To prepare a high -end waterproof leather, we must first make it both static and waterproof and dynamic waterproof. Based on this, it does not reduce the excellent performance of natural leather, especially the hygienic performance of leather, and even makes the leather more functional.

Second, leather leather waterproof mechanism

From the perspective of the appearance, it can be divided into two floors of coating and the leather. For Cheng Demon, we are used to calling the League of Levy. The previous description is that waterproof refers to the ability of leather to resist water absorption, water permeability and wetting by water. The first step of waterproof is to prevent the leather surface from being wet on the surface of the leather, which involves the moisture problem on the solid surface. The interaction between wetting is the interaction between the liquid and the solid, which involves the contact of Qi, liquid, and solidarity. The surface tension of three -phase contact surface has surface tension. Whether the wetting phenomenon occurs can be judged by the surface tension: When the surface tension of the liquid is lower than the surface tension of the solid, the liquid can extend the flat laying on the solid surface to wet the solid. During the surface tension, the liquid will shrink on the solid surface in the form of water droplets without spreading and wetting, that is, substances with high surface tension cannot wet the material with low tension. Therefore, in order to prevent leather from being soaked by water, the surface tension of the leather must be lower than the surface tension of water.

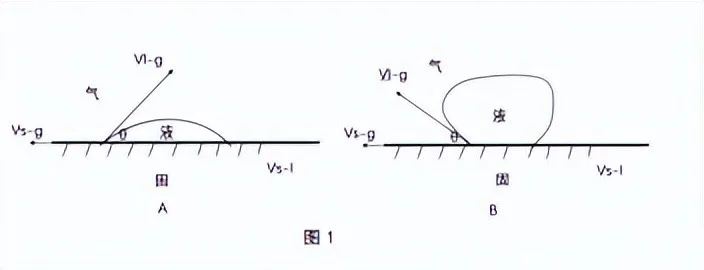

The degree of solid wetness is usually represented by contact angle. British scientist Thomas Young explained the problem when the famous Young equation proposed: When the liquid attached to the surface of the solid surface, the degree of moisturizing the solid surface can be represented by contact angle θ (or moisturizing angle): cosθ = vs -g-vl-g vs-l

In the formula 1: θ — The angle between the junction of qi-liquid-solid three phases, the angle between the tension between the qi-liquid and the gas-solid interface; The surface tension between the liquid-qi; the surface tension between the vs-l-solid-liquid. See the details below:

Figure 1 shows a diagram of the relationship between the contact angle and the surface tension. A is the condition of liquid wetting and solid, and B is the case where it is not wet. By determining the size of the contact angle, you can determine the wetting of the solid surface, which is generally 90 °. As shown in Figure 1 A, the interaction between hydrophilic solids and liquids. Its contact angle θ <90 °, liquid is placed on the solid surface, indicating that the liquid is easy to wet and solid; There is a contraction trend on the solid surface to form spherical liquid droplets. The contact angle θ> 90 ° indicates that the liquid is not easy to wet the solid, that is, the interaction between the hydrophobic solid surface and the liquid. The smaller the contact angle, the better the wetability is; when θ = 0 °, it indicates that the solid surface is completely wet, and θ = 180 ° is not wet at all. Therefore, in order to make the leather surface not wet and water -refusing, it is necessary to contact the angle θ> 90 ° in intuitive, and this can be achieved by reducing the surface tension of the leather surface. In addition to changing the contact angle to prevent the leather surface from being wet, it should also be noted that the leather itself is composed of collagen fibers, that is, there are countless capacity of different radius. The capillary phenomenon is extremely easy to occur, which will further increase the water absorption rate of the leather. Therefore, it is necessary to make the leather waterproof, and we should also consider the improvement of the fibrous hydrophobic performance of the leather.

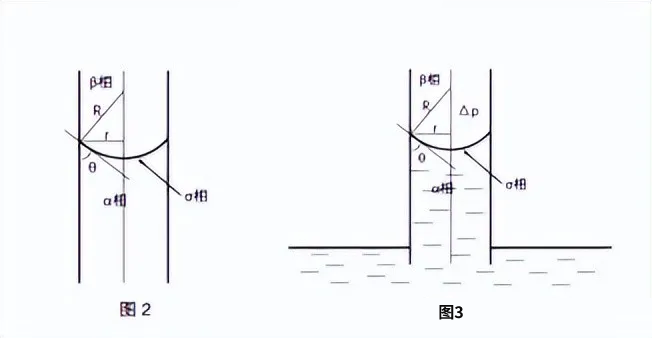

The capillary phenomenon is because the adhesion and condensation force of the molecular adhesion layer make the surface of the liquid surface bended. At the same time, the existence of the surface tension causes additional pressure on the curved liquid surface, which makes the liquid curved liquid surface and the liquid under the horizontal liquid surface. Pressure difference. This pressure difference rises or decreases the liquid in the capillary tube, which offsets the additional pressure, thereby balance the pressure difference. The liquid in the capillary tube rises or decreases. It can be judged by the Young-Laplace equation. Young-laplace equation describes the relationship between the additional pressure of the curved liquid and the surface tension and curvature radius of the liquid, as shown in the type 2. △ P = γ (1 R1 + 1 R2) Type 2: △ P — The pressure difference between the inside and outside of the liquid surface; the γ -surface tension coefficient; R1 and R2 — liquid main curvature radius. See the details below:

As shown in Figure 2 α, β, and σ three -phase coexistence systems in the capacity of the capillary tube. If the three -phase balance occurs in the capillary tube with a radius of R, the contact angle of the α is θ. In the schematic diagram of the young-laplace equation, if θ <90 °, then △ P <0, the liquid surface in the capillary tube is concave, and the force applied to the liquid below is pulling the liquid Enter the capillary tube and wet the solid; if θ> 90 °, then △ P> 0 The liquid surface of the capillary tube is convex. Essence Therefore, in order to make the capillary effect not occur, it is essentially to make the contact angle <90 °, but it can be achieved by reducing the surface of the inner surface of the capillary to change its surface tension.

Third, leather coating waterproof mechanism

The leather surface is the first to be exposed to water. In addition to changing the surface of the leather to prevent water from moisture, it can also replace the leather surface by adding a layer of water -resistant coating on the surface of the leather to make it the first line of defense of the leather waterproof. Essence The key to adding this coating lies in the wetness of the leather, the adhesion of the coating, and the penetration of the pulp. The bottom coating is the basis of the entire coating, and the sticky sticky is critical to the bottom coating, so the stickiness of the coating is essential. The impact on coating can be discussed from both physical and chemistry. The smooth surface is more unfavorable to the adhesion of the coating than the wear surface. The reason is that there are many wrinkles, small protrusions and irregularities on the surface of the wear. More conducive to sticking. The use of chemical cross -linking agents can improve the waterproofness and stickiness of coating. The penetration of the bottom slurry is also a key influencing factor. The leather itself is a porous substance with a fiber structure. According to the law of wetting and adhesive, the penetration rate of the pulp in the leather body is related to many factors.

The SandMeyer formula describes the relationship between penetration speed rate and surface tension, viscosity and contact angle.

Formula 4: Infiltration speed = pore degree × surface tension × cosθ viscosity

From Equation 4, we can see:

(1) The functional value (COSθ) of the wet angle (COSθ) is proportional to the penetration speed of the pulp, indicating that the wetting is a key role in the penetration of the bottoming pulp.

(2) Increasing pores, increasing surface tension, increasing the strings value (COSθ) of the contact angle, and reducing the viscosity of the liquid are conducive to increasing the wetting speed of the liquid. At the same time, the penetration of the bottom of the bottom should also be considered the penetration depth. The factors that affect the depth of penetration are basically the same as the factors that affect the speed of infiltration, but the penetration depth of the increased pulp is to reduce the viscosity, reduce the wet angle, and increase the surface tension of the pulp. It is contradictory to reduce wet angle and improve the surface tension. Therefore, the surface tension should be adjusted appropriately to make the pulp penetrate deeper. Although the penetration speed is proportional to the surface tension, the greater the surface tension, the greater the penetration speed, the greater the surface tension.

In addition to the factors mentioned above, the penetration of the bottom of the leather surface is also related to its concentration, the status of the leather (moisture content, pore degree, charge polarity, etc.) and coating methods.

Post time: May-30-2024